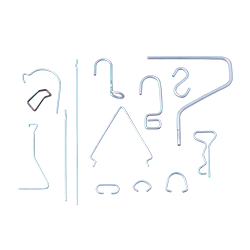

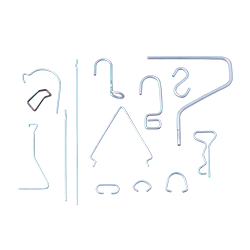

Custom Wire Forms

Cove West has been working with manufacturing companies and assisting in engineering custom wire forms for almost sixty years.

We take great pride in all the products we manufacture, and we stand behind long-lasting, high quality product at competitive pricing. Take a look through our website and reach out to us for a quote or give us a call at (714) 525-2930 when you’re ready to get started. We aim to understand our customers’ needs and will go the distance to best meet those needs. Bring us your wire idea!

For more than sixty years, Cove West has been a trusted manufacturer of custom wire forms that serve a wide variety of industries. Since 1960, the company has worked closely with customers to develop wire solutions that meet precise requirements, ranging from small specialty parts to large production runs. This long history demonstrates a commitment to precision, reliability, and consistency.

What Are Custom Wire Forms?

Wire forms are precision-shaped components made by bending wire into specific designs. These parts play an important role in many applications where strength, durability, and consistent performance are required. Because every project has different requirements, custom wire forms allow manufacturers to achieve the exact dimensions, shapes, and material characteristics that their products demand.

Cove West has the tools and expertise to produce wire forms in a wide range of styles, ensuring that each piece functions properly within its intended application. Whether the need is for electrical contacts, support wires, or structural components, the company has the resources to deliver the right solution.

Our Process: From Idea to Finished Product

Cove West supports customers from the earliest stages of design through production. Projects can begin with CAD files, prints, or even physical samples. From there, the engineering team provides guidance to refine the design for efficiency and functionality.

Prototyping is often part of the process, allowing customers to confirm that the wire form performs as intended before full production begins. Once a design is approved, advanced EDM tooling, CNC bending, and other fabrication technologies are used to produce wire forms that match the original specifications.

Production can scale to meet demand—whether small runs for specialized parts or high-volume orders for manufacturers. Every step is handled with a focus on consistency, quality, and dependable lead times.

Specialized Wire Form Applications

Over the decades, Cove West has manufactured countless custom wire parts. Some of the most common applications include:

Fuse Clips

Fuse clips provide a reliable way to secure fuses in electrical systems. They must be strong enough to hold components firmly, yet flexible enough to allow quick replacement when necessary. Cove West produces fuse clips that meet electrical safety requirements while maintaining long service life.

Paint Hooks

Industrial finishing operations rely on paint hooks to hold parts during coating or powder finishing. These hooks must handle repetitive use while maintaining shape and balance. Cove West fabricates paint hooks in various sizes and configurations, ensuring that parts are easy to hang, coat, and remove.

Vineyard Wire

Agricultural producers often use vineyard wire as part of trellis systems that support grapevines. Strength and weather resistance are critical qualities, as these wires remain exposed year-round. Cove West produces vineyard wire designed for durability, helping growers maintain healthy and productive vineyards.

These examples highlight just a portion of the company’s capability. Wire forms can also be adapted for automotive parts, industrial racking, fasteners, clips, and many other uses.

Industries Served

Because wire forms have such wide applications, they are used in many different industries.

- Automotive: clips, brackets, and fastening systems.

- Agriculture: vineyard wire and trellis support structures.

- Industrial finishing: paint hooks and hanging systems.

- General manufacturing: custom clips, supports, and specialty hardware.

This diversity demonstrates the flexibility of custom wire forming and the value of working with a company that has decades of experience across multiple sectors.

Contact Us

Cove Four/Cove West delivers high-quality products built to specification. Contact us today and let’s talk about your project or receive a production quote.